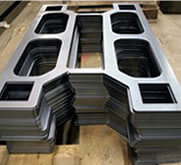

We are offering our clients a wide range of reliable sheet metal cutting services such as Laser Cutting, CNC Bending, Arc Welding, TIG Welding etc. We are involved in the precise metal fabrication of all types of steels such as Stainless Steel, HR, CRCA, Galvanized etc. We are also providing customized full assemblies/sub assemblies of cabinets, Machine covers/parts and electronic panels, electromechanical assemblies to our customer by our innovative techniques. Our range of sheet metal laser cutting jobs are renowned for their high accuracy, reliable and consistent, ecologically clean technology, low cutting noise and high level of specific output radiation.

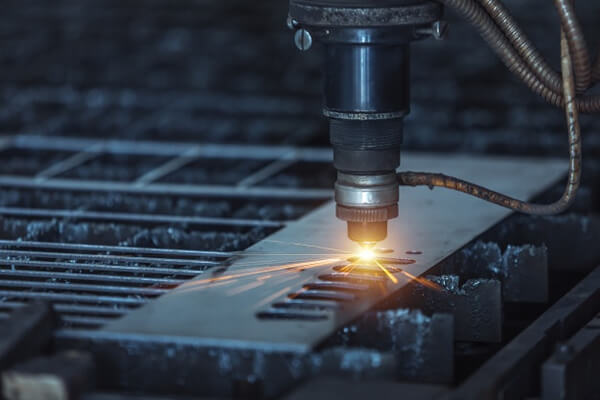

We offer laser cutting services for cutting the parts as per the customer’s need and drawings. We have TRUMPF Laser Cutting Machine with quality cutting of our own advanced production facilities.

Laser cutting has become the necessity of every industry in today’s time and the industrial purpose of laser technology is perfect for prototyping with no tooling cost.

The Laser Technology has some exceptional advantages which are as follows: